Mobile communication network news, MPO/MTP high-density optical fiber pre-connection system is currently mainly used in three areas: high-density environment applications in data centers, fiber-to-building applications, optical transceivers in optical splitters, 40G, 100G SFP, SFP+, etc. Connection application inside the device. This article focuses on why data centers use MPO/MTP high-density fiber pre-connection systems and how to choose such high-density fiber pre-connection systems.

Before introducing the current use of MPO/MTP high-density fiber pre-connection systems in these situations, it is necessary to make a brief introduction to MPO/MTP. In the field of communication and data transmission, the development of optical fiber connectors is far more developed than the development of copper connectors. According to incomplete statistics, so far, hundreds of fiber optic connectors have been developed, but there are more than a dozen that are actually used in a wide range. Throughout its development, fiber optic connectors have two distinct stages of development:

The first stage: in order to save space and develop towards miniaturization, fiber optic connectors have evolved from traditional FC, ST, SC to LC, MTRJ, E2000

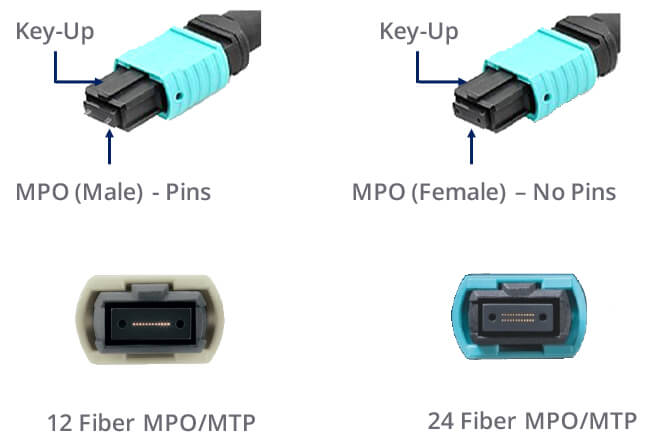

The second stage: not only to save space but also to meet the requirements of multi-core use, fiber optic connectors evolved from LC, MTRJ, E2000 to MU, MTP/MPOFIBER CABLING, now an MTP/MPO multi-core connector can meet 2 cores, 4 cores , 8-core, 12-core, 24-core, currently up to 72 cores.

The benefits of this development in the second phase are obvious. Look at the 40G and 100G requirements for fiber-optic network transmission specifications. Multi-core transmission, that is, 8-core or 20-core. In this way, MPO/MTP FIBER CABLING can meet the requirements of high-speed network applications in a small space. However, engineers who work on the site also bring great challenges and even impossible tasks. Of course, there is now a good alternative, which is the pre-connected system of the manufacturing plant.

The application of the MPO/MTP fiber pre-connection system in the data center has also been a matter of the past few years, and it is also the most important application of the MPO/MTP pre-connection system in China. The reason is not as noble as imagined, but it is actually an inevitable choice. Let me talk about the first reason: the data center space is always not enough. Just like the completion of Beijing’s subway for half a year, passenger traffic is full. This is actually a contradiction between limited resources and unlimited demand. This phenomenon is manifested in various fields in China today. To solve the problem of insufficient space, you can increase the space or increase the utilization of space. It is unrealistic to increase space in a designed data center. Increasing the space utilization rate means increasing density. As the two major wiring systems in the data center: copper cables, cable cabling systems, in fact, copper systems can also use high density, but this high-density space savings are limited. Because it is not only impossible to find a balance between the high frequency and the larger line; the electrical transmission performance of the cable at high frequency is not easy to meet, and the high-frequency electronic signal is also transmitted in the multi-core copper transmission. A series of questions. Of course, in order to install a convenient copper pre-connection system on site, this is another topic, no matter here. Therefore, in order to get more transmission bandwidth in the same space, switching to optical cable transmission is an inevitable choice, but this does not mean that a high-density optical fiber pre-connection system is required.

Original Article Source https://www.mscbsc.com/viewnews-94461.html