Since ASON (Intelligent Optical Network) is built on various transmission technologies, that is, an independent control plane is added on the transmission plane SDH and the Optical Transport Network (OTN), it supports various types of transmission networks currently available. Services for rate and different signal characteristics (such as format, bit rate, etc.). The ASON network can provide a fixed bandwidth transmission channel between two client network elements, the channel being defined between the input access point and the output access point of the optical network.

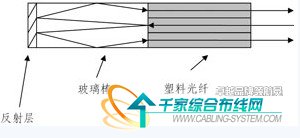

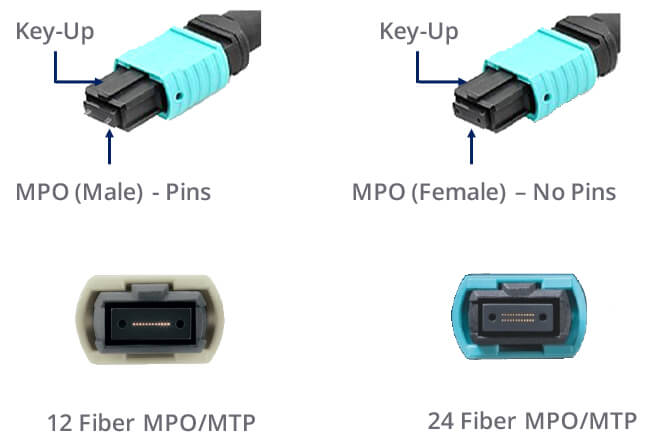

According to the transmission mode of light in the optical fiber, it can be divided into single mode fiber and multimode fiber.

The ASON business has the following aspects:

SDH service, supporting SDH connection particles VC-n and VC-n-Xv defined by G.707;

OTN service, supporting OTN connection particles ODUk and ODUk-n-Xv defined by G.709;

Transparent or opaque optical wavelength service;

10Mb/s, 100Mb/s, 1Gb/s and 10Gb/s Ethernet services;

Storage Area Network (SAN) services based on Fiber Optic Connection (FICON), Enterprise System Connectivity (ESCON), and Fibre Channel (FC).

ASON is scalable to new business types.

ASON can support multiple types of business models, each with its own business attributes, target market, and business management needs.

Business connection topology type

To support enhanced services (such as bandwidth on demand allocation, diversity circuit assignments, and bundled connections, etc.), ASON should support the separation of call and connection control. The separation of call and connection control can reduce excessive call control information for intermediate connection control nodes, eliminating the heavy burden of decoding and interpreting messages. The connection topology types supported by ASON include bidirectional point-to-point connections, unidirectional point-to-point connections, and unidirectional point-to-multipoint connections.

Since the call and the connection are separated, one call can correspond to multiple connections, and the current two-way point-to-point connection is the most important connection.

Business connection type

The ASON network supports three types of service network connections: permanent connection (PC), switched connection (SC), and soft permanent connection (SPC).

Both PC and SPC connections are managed by the management plane. The difference between PC and SPC is whether the connection is established in the optical network by using network management commands or real-time signaling. These two methods are service connections initiated by the operator.

The SC connection is initiated by the UNI signaling interface, and the service request of the user is sent to the operator through the UNI of the control plane (including the signaling proxy), that is, the user directly initiates the establishment of the service connection.

Business level

The current transmission network cannot formulate a corresponding tariff policy according to the service level, which causes waste of resource allocation, and the ASON network can conveniently divide the priority of the service circuit to provide a transmission service circuit with a service quality agreement (SLA). Customers have different requirements for the reliability of different connections. These requirements can be expressed in terms of “service level”. In an ASON network, the service level is mainly achieved by mapping to different recovery, protection options, and priority of related connections, such as establishing priority, maintaining priority (whether it can be pre-idle), and restoring priority.

The establishment of the priority mainly refers to the establishment response time of the service, which is to establish a service connection in the day, hour or minute.

Maintaining the priority (whether it can be pre-idle) mainly refers to whether the system will be idle to carry more important services in the event of other system failures, and the service connection itself has no protection.

Recovery priority is the recovery time and recovery level (such as the percentage of recovered services) in the event of a system failure.

Mapping a single business class to a range of protection and recovery options, each with a different choice. The control plane supports setting based on the priority of each link and supports bandwidth resource reservation as a recovery purpose and normalization of the failed repair route. Commonly supported service connection levels include: dedicated connections (1+1 and 1:1), shared protection (1: N and M: N), unprotected (transmitted on the primary circuit), unprotected services (in the protection circuit) On the transfer) and so on.

Service access method

In order to connect the service to the ASON network, the user first needs to establish a physical connection with the carrier network on the transport plane. According to the location of the carrier network and the customer, the service access can take intra-office access (the optical network element and the client network element are in one place), the direct remote access (with a dedicated link to the user end), and the connection Remote access to the subnet and dual-homing access.

ASON must support dual-homing access. Multiple addresses should not be required for dual-homing access for the same client device. Dual-homing access is a special case of access. The main purpose of adopting dual-homing access is to enhance the survivability of the network. When access fails, the customer’s service can rely on other access without interruption. Client devices can access the core network/operator in a dual-homed manner (two different paths).

From a security perspective, network resources should avoid unauthorized access. Service access control is a mechanism that restricts and controls the entity’s attempts to access network resources, especially through the UNI and external network node interfaces (E-NNI).

The Connection Admission Control (CAC) feature should support the following security features.

1. CAC applies to all entities accessing network resources through UNI (or E-NNI). The CAC includes an entity authentication function to prevent an imposter from fraudulently using network resources by pretending another entity. An authenticated entity will be given a service access level based on configurable policy management.

2. Mechanisms should be provided on the UNI and Network Node Interface (NNI) to ensure client authentication and link information integrity, such as link setup, teardown, and signaling information, for connection management and to prevent service intrusion. The UNI and E-NNI should also include CAC-based application charging information to prevent forgery of connection management information.

3. Each entity can utilize network resources through the authorization of the operator management policy.

Original Article Source https://www.mscbsc.com/viewnews-77189.html