Using fiber optic color codes in the data center can effectively help technicians better manage fiber optic cables and reduce human error. Workers can easily obtain information about the device by viewing the cable color code, which simplifies the redundant inspection process. Making full use of the optical cable color coding system can save a lot of working time. The widely accepted color coding system and its important functions are described below.

Introduction to Cable Color Code System

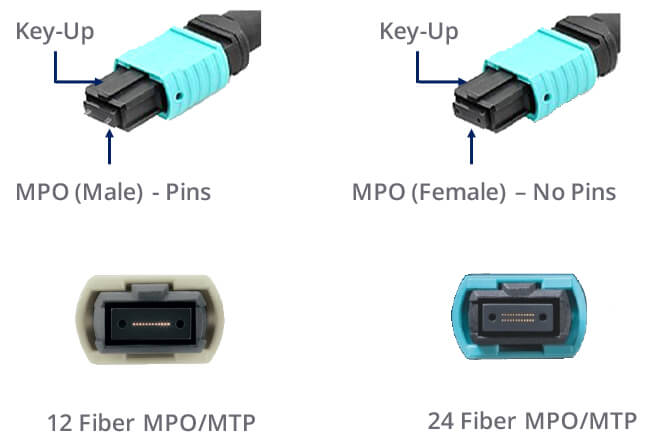

Fibers, bundles, and straps in fiber optic cables are often labeled with different color codes for easy identification. Many countries use this color code system. All of these systems are characterized by the use of 12 different colors to identify fibers that are gathered together in a common bundle, such as bundle tubes, drawstrings, yarn rolls, or other types of bundles.

Different countries and regions use different color code standards. For example, in Sweden, the S12 standard is used for micro cables and nanocables. The Type E standard is defined by Televerket and Ericsson used in Sweden. Countries such as Finland use the FIN2012 standard, but a color coding system generally accepted in the world, namely the TIA/EIA-598 standard.

TIA/EIA-598 color code specifications The following figure shows the cable color coding for the TIA/EIA-598 standard. If more than 12 fibers or bundles are to be distinguished, the color sequence is usually repeated on the fibers and bundles with ring marks or lines. As for the cable jacket, the orange, yellow, light green and black color scales are used for distinguishing.

The role of the cable color code in the data center

(1) Differentiating the cable grade

As mentioned above, the outer jacket color code can identify the cable grade. The OM1/OM2 cable is usually orange-sheathed, the OM3/OM4 cable is light green, the single-mode cable is yellow, and the hybrid cable (indoor/outdoor and outdoor cables) is black. One thing to note is that mixing OM1 and OM2 or OM3 and OM4 cables can be cumbersome to handle.

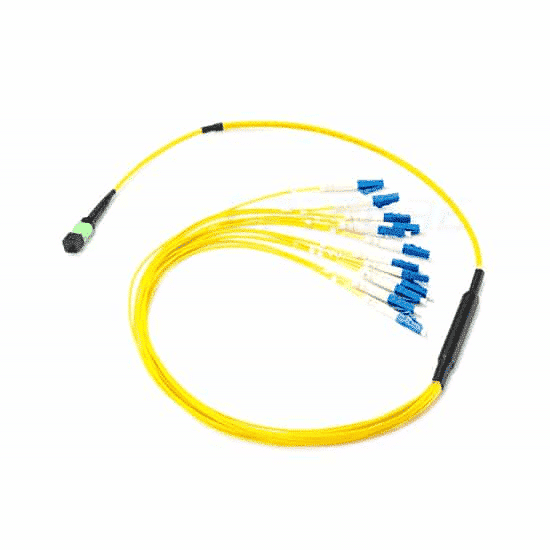

(2) Identify the fiber jumper

Marking fiber patch cords with color codes can reduce the possibility of human error. For example, a mission-critical jumper can be highlighted in red and the technician can be shown that the red jumper can only be moved with proper authorization or supervision. Again, the color of the fiber optic connector needs to be consistent with the fiber-level color standard, which will make it easier for technicians to use the correct connector on the fiber optic cable.

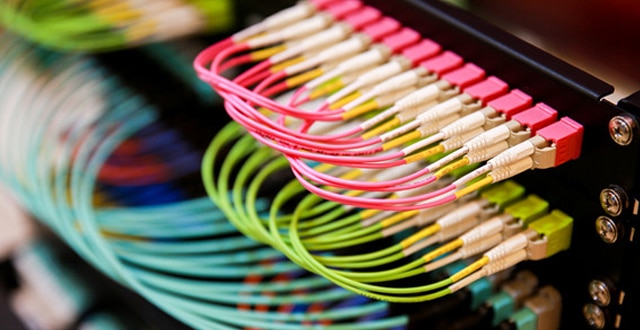

(3) Differentiating different ports

Color-coded port icons help identify different network routes based on internal requirements. Network management can be simplified by marking each patch panel port.

(4) Distinguishing Connector Sheaths

Staff can use color codes on the boot connectors to help technicians maintain proper parallel grouping of switch ports, making routine maintenance, movement, additions, and changes easier. If you change the connector color, you need to make sure that the cable color represents the fiber grade to avoid confusion. Workers can also change the color of the boot connector to differentiate between different deployments of the optical network, allowing technicians to easily view the contrast within the panel.

Conclusion

Visual management is more intuitive for experts who manage and maintain data centers. The fiber color code provides an ideal and easy way to solve fiber routing problems. Inside the cable, the fiber buffer can also be color coded in standard colors for easy connection and splicing. Therefore, if people are still plagued by problems such as fiber jumpers, it is a good idea to use fiber color code systems.

Edit: Harris

Original Article Source http://www.jifang360.com/news/2019412/n6592117478.html