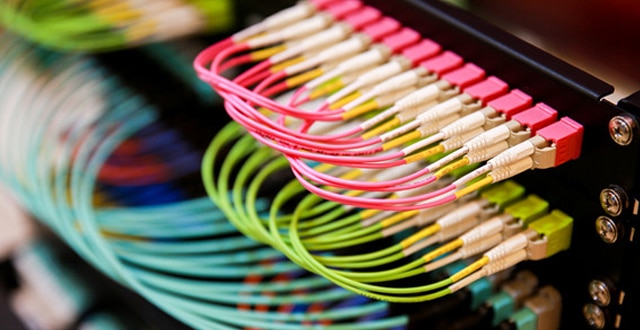

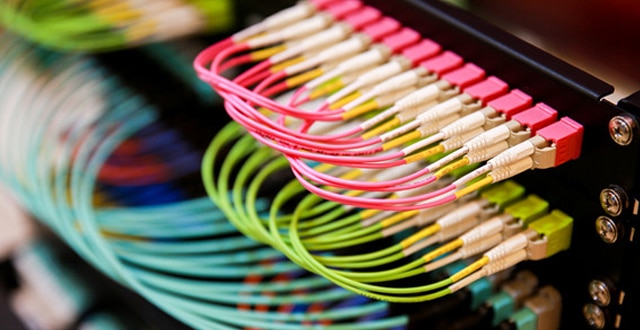

As we all know, the fiber jumper is used to make the jumper from the device to the fiber-optic wiring link. It has a thick protective layer, which is generally used for the connection between the optical transceiver and the terminal box. So you know how to make fiber jumpers? What are the precautions for fiber jumper construction?

How to make fiber jumpers

1 Steps for skipping content:

The first step: identify the light and the room, find the splitter.

Step 2: Identify the splitter number.

Step 3: Find the splitter port configured on the work order.

Step 4: Find the port of the cable core of the access user.

Step 5: Jump from the splitter port to the user cable port.

2 Basic knowledge and specifications of fiber jumper:

1) The fiber-optic operation must meet the principles of ODF frame, light communication, tidy inside the integrated box, beautiful wiring, easy operation, and less space.

2) The length of the jumper must be within the range of 500mm.

3) Jumpers of insufficient length shall not be used. It is not allowed to use flanges to connect two jumpers.

4) Each jumper should ensure that the radius of curvature is greater than 400mm.

5) General requirements for fiber removal:

1 For the fiber on the upper line, the cable should be off the outside of the ODF frame. Select the most suitable fiber column for the remaining fiber volume, and move the fiber upwards on the inside of the ODF frame. The horizontal edge is on the lower edge of the ODM and is perpendicular to the corresponding terminal.

2 One jumper is only allowed to go up once in the ODF frame (along the outside of the ODF frame), once on the side (along the inside of the ODF frame), and take a fiber column. It is forbidden to entangle, cross and hang between the multiple fiber columns. That is, there must be no filament winding on the upper edge of each disc.

3 The specific situation of the site should be stipulated after the initial preparation of the jumper.

4 All jumpers must be placed in the ODF frame. It is strictly forbidden to deploy outside the aircraft and fly the line.

5 The super long jump fiber for emergency use shall be hung on the inner fiber disc according to the rules, and shall not affect the future fiber jump.

3 Jumper type and length control

1) Select the corresponding fiber jumper (SC-SC, FC-FC, SC-FC) according to the flange head on the splitter and the splitter box.

2) The fiber jumper from the splitter to the user table, the length of the length is controlled within 50CM, and the pigtails of 1m, 2m, 2m5, 3m are generally selected.

3) The ONU and the fiber terminal jumper in the user terminal box generally use 50CM short pigtail.

4 Jumper label management and specification

1) All jumper labels must be labeled with the machine and no handwriting is allowed.

2) In the machine room, light communication, and corridor, the fiber-optic to the user’s leather cable must be attached to both ends of the fiber-optic cable.

3) The effect after completion is uniform specification length, according to the gap of the terminal position, the labels are not staggered.

4) The front side is the name of the light path, and the reverse side is the light path code and barcode, and the orientation is uniform.

5) The change text hangs down with the pigtails, naturally facing up.

5 Perform the necessary optical path test

After each fiber path jump is completed, it needs to be tested. The test steps are as follows:

1) Test the wavelength of the splitter at 1490 with an optical power meter, and the optical power should be less than -22dB.

2) The user end tests with the 1490 wavelength of the optical power meter. The receiving power should be less than -23dB, and the maximum sensitivity of the ONU is generally -24dB.

3) Use the ONU device to debug the Internet for the user.

4) If there is no light, you can judge whether the fiber is wrong by the visible light source (red light).

5) If there is no fiber but still no light, when the loss is large, the ONU can not work normally, and the cable maintenance department can be informed.

6 Resource Management

It is strictly forbidden to change the fiber order of the construction sheet without authorization. The optical path resources need to be changed during the loading and maintenance process. The relevant information of the optical path is recorded on the work order and timely reported to the resource department for updating.

What are the precautions for fiber jumper construction?

1 Types and uses of pigtails

According to the existing ODF shelf and device port standards, fiber jumpers can be classified into the following types:

(1) According to the interface type: the pigtail interface can be divided into three interfaces: FC, SC, and LC. The two ends are FC-FC, SC-SC, LC-LC, FC-SC, FC-LC, SC. -LC, a total of six types of fiber jumpers.

(2) According to the length of the interface: the pigtails are 1.5 meters, 2 meters, 3 meters, 5 meters, 10 meters, 15 meters, 20 meters. We usually use 3 meters, 5 meters, 10 meters, 15 meters, and 20 meters.

(3) Use: FC interface is used for ODF frame to connect remote core; SC interface is used for ODF frame (less) and equipment, such as OLT and ONU device interface in EPON, photoelectric converter interface, etc.; LC interface only Used on the interface of the device. Two of the three core interfaces are combined to achieve a physical connection between the ODF and the ODF shelf, between the ODF shelf to the device, and between the device and the device.

2 Preparations and precautions outside the field before fiber jumper:

Before the fiber jumper, it is generally based on the needs of the business, there will be a need for a fiber jumper. But for different needs, the equipment to be jumped is different, and the preparation work that needs to be done is different. Therefore, before the fiber jumper, there must be clear working ideas and clear work objectives. Otherwise, there will be cases where the jumper is not brought or not so that the work task cannot be completed on time, and the work target cannot be realized on time. , affecting the development of the company’s business. Therefore, preparation before the fiber jump is critical to the achievement of the work objectives. Preparations outside the site are generally outside the computer room, and the following preparations are required. Finally, there are matters needing attention.

1) Preparation work outside the field before fiber jumper:

1 Working ideas: What is the purpose of the jumper? What equipment is needed to jumper? What interface is the device? What type of fiber jumper do I need to use? Do I need to prepare an optical module? Do you need other tools? These are all things that need to be considered in advance.

2 Tool preparation: optical power meter (including test fiber jumper), red light pen, tube sleeve, label paper, oil pen, notepad, pliers, electric tape.

3 Material preparation: fiber jumper, optical module, the quantity, type or length of the corresponding material is determined according to requirements.

4 Disk information preparation: If the interconnection between different computer rooms, you need to know the information about the machine room and record it on the notebook.

2) Precautions before the field of fiber jumper:

1 If you need to bring a module, you should pay attention to the module type, distance, wavelength, and other parameters;

2 The core should pay attention to the type and length of the interface, and pay attention to whether it is necessary to cross the cabinet, how far apart the cabinet is, and whether it is necessary to walk the distribution frame.

3 Note that with spare modules and fiber jumpers, at least one spare module and one pair of corresponding jumpers must be prepared.

3 Preparations in the field before the fiber jumper

1 Untie the pigtail tape and unfold the two pigtails. After the whole fiber is unfolded, the same interface is put together. After straightening, the two fiber jumpers are bundled together with electric tape.

2 If you jump into the core of different computer rooms, you can first contact the colleagues in the remote computer room to test whether the pigtails can be used normally, whether the ODF shelf is faulty, and whether the cable light loss is normal; if it is the equipment in the machine room Connected, connected to relevant equipment, test whether the pigtail can be used normally;

3 Use Notepad to copy the serial number of the module to be used, the length and type of the core, to facilitate asset management.

4 Precautions in the field of fiber jumper

1 Jumping is divided into three cases: the same cabinet jumper, adjacent cabinet jumper, and cross-rack jumper. The difference is that the pigtails across the cabinet are protected by bushings when they cross the cabinet, and the patch panels are used for the patch panels.

2 When the pigtail is connected, connect one end of the core to the device, and the other end is routed from the left side facing the cabinet. The excess pigtails are wrapped in a circle (not folded into a straight line) and wrapped with electric tape. Well, connect the other end to the device or the ODF frame. The ODF frame enters the line from the left side hole of the ODF frame, and the flying line cannot appear.

After 3 good cores, label paper should be attached and labeled according to the naming requirements.

4 After the label is placed, the registration of the core of the ODF frame should be done. If the main core is jumped, the use of the core should be used (the local and the opposite information is written on the label paper). And use the notepad to record it.

5 Collect the protective caps of the module and pigtails and place them in the small box at the bottom of the cabinet for future use.

5 Finishing work after fiber jumper:

Before leaving the machine room:

1 Contact the relevant colleague to test whether the core is connected and whether the jump target has been completed;

2 After confirming that the fiber-hopping work is successfully completed, carry out on-site tool finishing, and clean the waste materials such as the pigtail packaging bag to keep the environment of the machine room clean and tidy;

3 Close the room lights, check again if something is in the machine room, and pay attention to lock the machine door when leaving.

The above is all the contents of the fiber jumper and the fiber jumper construction precautions. Of course, the fiber should not be excessively bent and looped during use, which will increase the attenuation of light during transmission. Be sure to protect the fiber connector with a protective sleeve after use. Dust and oil can damage the coupling of the fiber.

Original Article Source http://cabling.qianjia.com/html/2019-05/22_337862.html