ICCSZ News In the enterprise data center, OM3/OM4 multimode fiber is currently used as the Fibre Channel FC transmission medium to connect servers and storage devices. High-performance server and storage technologies continue to drive FC channel rates, while also requiring FC channels for higher reliability and lower cost. This article will focus on high-speed OM3/OM4 multimode fiber connections between servers and storage devices.

FC Fibre Channel – supports high rates

Fibre Channel FC is the preferred choice for server and storage connectivity due to its high speed, low jitter, and high reliability. As server and storage technologies continue to evolve, the rate of Fibre Channel FC continues to increase.

Rate map of Fibre Channel released by FCIA

A detailed description of past, present, and future Fibre Channel

Today, multi-core processor servers deployed in enterprise data centers range from 4 to 12 core processors. Each processor typically has 2 GHz of processing power. With 12 cores, the processor capacity is 24 GHz. In addition, the server now generally uses PCIe3 (8G / line) and PCIe4 (16G / line) bus interface, has gradually solved the bus interface bottleneck caused by the increase in the number of processors. Increased server computing power requires higher Ethernet data rates and higher Fibre Channel rates. Future server bandwidth trends will be Ethernet 50/100Gbps (NIC) and 64 Gbps Fibre Channel (HBA) interconnects.

Compared to traditional hard disk drives (HDDs), all-flash arrays (AFAs) offer high data density, high endurance, low energy consumption, and rack space savings, significantly improving storage performance. According to the Brocade demo, it uses 32G Fibre Channel to access 8G of flash memory, which is 71% less than the response time of using 8G Fibre Channel.

Data center multimode fiber connection distance

Based on Ethernet and Fibre Channel transmission standards, technology development, and commercial viability, Corning established a model for data center multimode and single mode fiber connection channel lengths. The data shows that as Ethernet rates increase from 10G to 40G and 100G, and Fibre Channel rates range from 8G to 16G and 32G, data center users deploy OM3/OM4 multimode fiber, with more than 90% of the distance being within 100 meters. In other words, for the vast majority of data center users, the 100-meter channel distance is sufficient for their needs.

FC Fibre Channel – mainly using OM3/OM4 multimode media

Fibre Channel FC is a point-to-point connection. OM3/OM4 multimode fiber is the primary medium for short-range transmission with a transmission distance of up to 150 meters. The 16GFC and 32GFC channels are now deployed primarily with OM3/OM4 multimode fiber. In addition, OM3/OM4 multimode fiber uses VCSELs, so it is more economical.

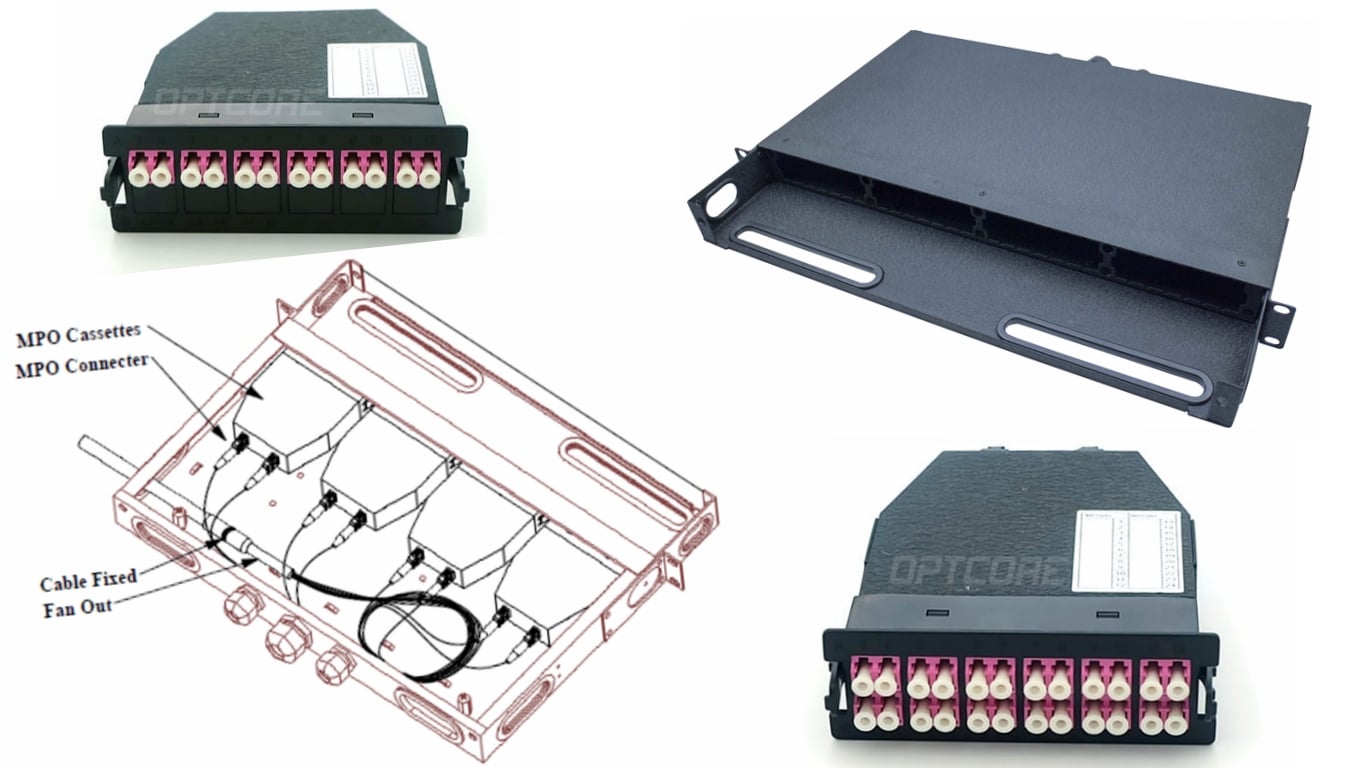

To date, Fibre Channel FC uses a small form-factor pluggable (SFP+) transceiver with a duplex LC interface in a storage area network (SAN) connection. The pre-terminated MTP cable is usually deployed as a trunk under the bridge or overhead floor between the server cabinet and the storage device cabinet. The MTP/LC module or fan-out jumper is used in the equipment cabinet to convert to the LC connector. Of course, using the MTP/LC fanout jumper can effectively reduce the number of cables and reduce the difficulty of installation and maintenance. At the same time, the MTP/LC fanout jumper provides stepped LC leg length, which can better meet the space of the line card port.

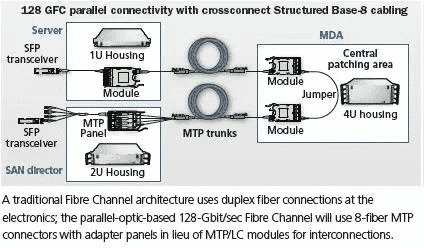

The Fibre Channel FC-PI6 standard includes the 128GFC protocol, which uses a QSFP transceiver and an 8- or 12-pin MTP interface. The 128GFC uses parallel transmission technology. Parallel transmission differs from the traditional two-core serial method in that it transmits 32GFC per core fiber, namely: 4-core bearer transmits signal (4x32GFC) and 4-core bearer receive signal (4x32GFC). 128GFC is also the first to be defined as a Fibre Channel transmission technology for parallel transmission. Future FC-PI7 will also promote 256 GFC parallel transmission.

Initially, 128GFC is expected to be deployed on the switch internal link (ISL) and use MTP to connect the entire link. Parallel transmissions will use 8-core MTP connectors and adapter panels instead of MTP-to-LC interconnects compared to traditional Fibre Channel duplex serial connections.

The fiber-optic transmission channel FC needs higher speed to improve the response speed of the server and storage devices. Currently, the distance of the FC channel is mostly within 100 meters, so the OM3/OM4 multi-mode fiber connection is a wise choice for cost-effective.

Disclaimer: All information indicated as other sources is transferred from other platforms, the purpose is to convey more information, does not represent the views and positions of this site. Please contact us if there is any infringement or objection.