With the rapid development of data centers, applications such as cloud computing and cloud storage have gradually penetrated various industries, and the bandwidth requirements for network communication have also increased rapidly. High-speed, high-capacity, and high-bandwidth often require more space and higher costs. This long-term contradiction, MTP / MPO fiber wiring standard has become the best solution for high density and high bandwidth. There are two kinds of fiber optic connection systems, MTP and MPO, which are very similar in the market. They are compatible with each other to a certain extent, so what is the difference?

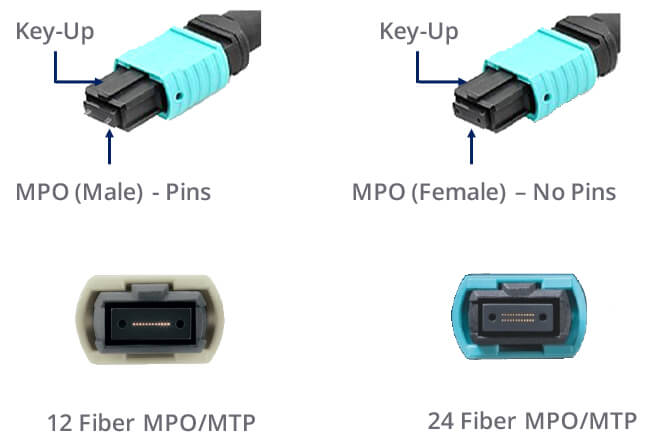

MPO is the abbreviation for “multi-fiber pull off”. The ferrule of this connector has more than one core and is mechanically snapped into place.

Nowadays, various manufacturers in the market have a variety of MPO designs. The performance and cost of different types of connected products are very different. Some products make their performance more outstanding. Some MPO connectors can match many different brands of products, but some do not. This compatibility depends on how close these connectors are to standard products. For a complete definition of the MPO connector, please refer to the implementation of IEC-61754-7 and EIA/TIA-604-5 (aka FOCIS 5).

What is an MT ferrule?

The MT is a mechanical docking transmission with a multi-core number (usually 12 cores). The performance of the connector is determined by the accuracy of the fiber alignment and whether the alignment accuracy is stable after the connection. Ultimately, this alignment accuracy is determined by the eccentricity and spacing of the fiber and the matching accuracy of the guide pin and fiber. The performance of any MPO connector can be improved if the deviation of the guide pin and the molding process can be reduced during the production process.

What is an MTP? Fiber Connector?

The MTP connector is a high-performance MPO connector with multiple innovative designs. The MTP fiber connector is enhanced in optical and mechanical performance compared to conventional MPO connectors. The MTP connector is fully compliant with the professional standards of all MPO connectors, including EIA/TIA-604-5 FOCIS 5 and IEC-61754-7.

MPO-type connectors are industry-standard, interchangeable MTP connectors, which means that it is possible to replace MPO connectors with MTP connectors for better performance. Most of the MPO connectors that follow the old design have quite limited performance and do not provide the same high performance as MTP fiber connectors.

Why is the MTP connector described as a high-performance MPO connector?

The performance and usability of the specially designed MTP connector are improved compared to the MPO connector. This design feature of MTP is unique and patented. The main features are as follows:

1. The outer frame of the MTP fiber optic connector can be easily removed.

The MT ferrule design ensures performance without loss during rework and regrinds during production. Yin-positive can be flexibly changed even after assembly, and the ferrule can be over-interfered after assembly.

2, MTP fiber optic connector floating ferrule can improve the transmission performance when mechanical docking. The two connectors can be allowed to maintain good physical contact with the mating ferrules under the influence of external forces.

3. The elliptical guide pin (PIN) of the MTP fiber connector is made of stainless steel. The elliptical guide pin can improve the precision of the butt joint and reduce the wear of the guide hole so that the MTP fiber connector can maintain high-performance transmission more permanently.

4. There is a metal clip in the MTP fiber connector to fix the push ring. Specific characteristics:

Prevent the loss of the guide pin;

Concentrating the pressure generated by the spring;

Preventing the spring from touching the friction fiber during mechanical stretching to cause damage to the fiber;

5. The spring design of the MTP fiber optic connector maximizes the band gap of the 12-core and multi-core ribbon applications to prevent fiber damage.

6, MTP fiber optic connectors have at least four standard matching parts, can be adapted to different types of fiber optic cable, more practical, including:

around the cable with a loose structure;

a ribbon cable with an elliptical outer cover;

Ribbon bare fiber;

The ultra-short-tail connector is ideal for applications in tight spaces, reducing volume by 45%.

Can the MT ferrule be cleaned in the usual way?

The best way to clean the dust and oil on the MT ferrule that affects optical performance is to use an advanced dry cloth cleaning kit, such as NTT-AT OPTIPOP, which is simply because it involves only a single channel. When using the above cleaning components, the contaminants will be completely removed. On the contrary, the use of low-quality fabrics or cotton swabs can remove the contaminants on the surface of the fiber, but the dirt will still exist on the edge of the ferrule, and the ferrule end faces are easily worn, causing serious Data loss.

The OPTIPOP series of cleaning components are designed for yin and yang fiber optic connectors and can also be used with single core ceramic ferrules. OPTIPOP cassette and card cleaners use a refillable cleaning cloth that can be used for a long time and is less expensive to clean than traditional cleaning methods.

Responsible Editor: DJ Editor

Original Article Source http://www.jifang360.com/news/201562/n330268516.html