As the demand for different kinds of information is also increasing, the accompanying ever-increasing demand for new services such as IP data, voice, and multimedia images has prompted the network environment of major network operators to become overwhelming. In the past, traditional metropolitan area networks and access networks, which mainly used to carry analog voices, have been unable to meet the requirements of a variety of new service transmission and processing in terms of capacity and interface types. As a result of the rapid advancement of social information, the technologies and equipment that provide new services for metropolitan area networks and access networks have rapidly developed. Among them, the development of MSTP (Multi-Service Transport Platform) and PON (Passive Optical Network) is the most representative. They are based on fiber-optic transmission technology and provide the best of various new service bearers on the metropolitan area network or access network. solution.

Fiber-optic cable access technology is the development direction of broadband networks in the future. Its development is also inseparable from the development and support of fiber access equipment, just like fish and water. Talking about the fiber access equipment has to mention its three generations of development experience: the first generation of large-scale PDH (fiber optic transceiver) equipment, including point-to-point and star-type office equipment, does not have aggregation function. All adopt PDH transmission protocol, and there is no optical interface specification. User services, such as E1 and data services, are multiplexed through the private PDH protocol and transmitted to the central office equipment via optical fibers. The central office equipment taps the PDH optical signal according to the proprietary protocol, and converts it into a PDH interface such as E1, and then connects to the metro backbone/aggregation device through the cable through the DDF distribution frame. Due to the limitations of the PDH protocol, various types of fiber access devices are quickly out of date.

The second generation In view of the defects of the first generation equipment, some PDH equipment manufacturers have developed a piece of second generation equipment, that is, adding an SDH (dense optical wave multiplexing) terminal card to the central office equipment. The private PDH protocol is still used between the central office and the remote device, and the aggregation function is provided at the central office to multiplex the original E1 signal through the SDH terminal card and provide a standard SDH interface. It mainly solves the interconnection problem and unified interface standard between the central office equipment and the metro backbone equipment.

The third generation is SDH pass-through equipment, including converged and non-converged types. Due to the wide coverage of the new services, the new generation of SDH pass-through devices can be automatically adapted to the SDH for transmission according to the SDH specification. The non-aggregated remote device can be directly connected to the metropolitan area network aggregation layer node through the SDH optical interface. There are fewer service interfaces on the aggregation layer network. The aggregation type is inserted into the SDH aggregation device at the central office to aggregate VC12 services from multiple directions to the uplink SDH interface, thus saving the number of STM-1 interface cards on the large-capacity backbone node device. It mainly solves the compatibility problem of each device and is convenient for future upgrade and maintenance.

With the development of fiber access equipment to date, due to the continuous updating of fiber access technologies and the increasing number of manufacturers joining, the categories of fiber access equipment are becoming more and more obvious, mainly in three categories:

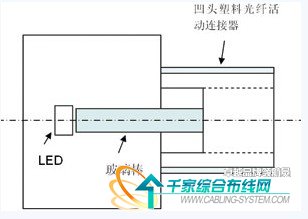

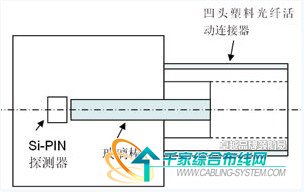

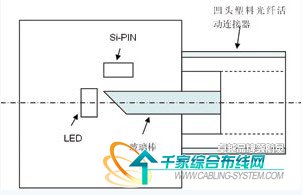

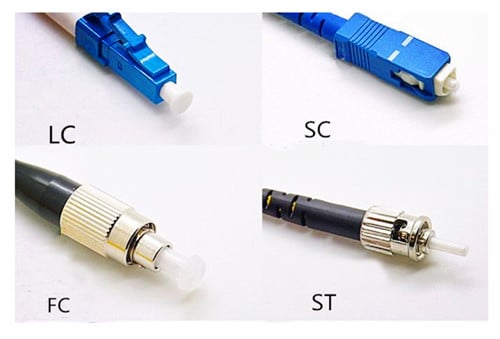

(1) Optical fiber communication Continued text components (for communication and computer network terminal connections), such as fiber jumpers, fiber connectors (boxes).

(2) Optical fiber transceiver (for computer network data transmission), such as fiber optic box, fiber coupler and wiring box (rack).

(3) Optical cable engineering equipment, optical cable test instrument (for large-scale engineering), such as optical fiber fusion splicer, optical fiber loss test equipment.

For the first two categories, we can often understand and contact the fiber access equipment products. The following small series introduces two major types of equipment:

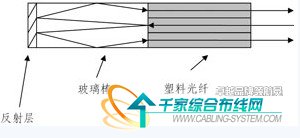

fiber optic communication and text fiber transceivers: the fiber jumper is without connection. The cable pair or cable unit of the unit is used to interface with various links on the distribution frame. Fiber optic patch cords are used for long-haul and local optical transmission networks, data transmission and private networks, and various test and automation systems.

fiber optic connector (box) is mainly used for the connection between fiber and fiber, fiber and device.

Fiber optic boxes are used to transmit digital and similar voice, video and data signals using fiber optic technology. Fiber optic boxes are available for direct or desktop installation. Particularly suitable for high-speed fiber transmission.

Fiber module card

Fiber

Coupler Fiber Coupler (Splitter) is a component that splits optical signals from one fiber into multiple fibers. It belongs to the field of optical passive components, in telecommunication networks, cable TV networks, and users. It is applied in the loop system and the regional network, and the largest item is used in the passive component of the fiber connector. The fiber coupler can be divided into a standard coupler (double branch, unit 1 × 2, that is, the optical signal is divided into two powers), a star/tree coupler, and a wavelength multiplexer (WDM, if the wavelength is high density, that is, the wavelength spacing is narrow, it belongs to DWDM), and the production method includes three types of sintering (Fuse), micro-optics (Micro-Optics), an optical waveguide (Wave Guide), while the production by sintering method is the majority (about 90). %).

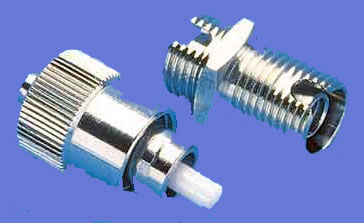

ST coupler

Six-port SC coupler board

Single and multimode fiber converter

single and multimode fiber transceivers are used for data communication between optical cables, allowing users to expand the scale of UTP networks using single mode or multimode fiber, and are widely used in Ethernet data communication to extend the transmission distance. The expansion and extension of the network are achieved through fiber optic links.

video multiplexer adopts the most advanced digital video, high-speed transmission technology of Gigabit fiber and all-digital uncompressed technology, so it can support any high-resolution motion and still image without distortion transmission; overcome the conventional analog frequency modulation and phase modulation. The amplitude modulation of the multi-channel signal of the amplitude modulation optical transceiver is severe, the interference is serious, the transmission quality is inferior, and the long-term working stability is poor. It can also provide multiple channels of video, audio, data, telephone voice, and Ethernet transmission on the optical fiber at the same time, which greatly saves the investment cost of the user equipment and improves the utilization of the optical cable. Widely used in security monitoring, highways, electronic police, automation, intelligent community, customs, electricity, water conservancy, petroleum, chemical, and many other fields.

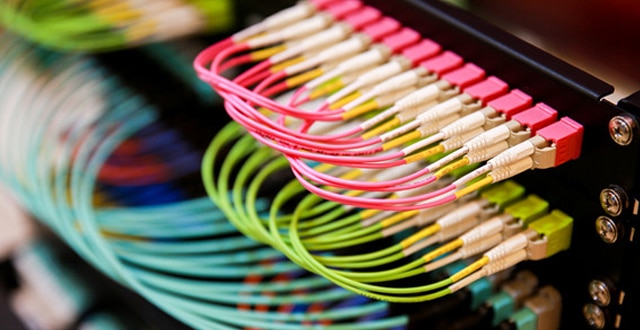

fiber distribution equipment is designed for the fiber-optic communication equipment room. It consists of a fiber distribution unit and a cabinet or rack. The maximum wiring capacity of each unit is 24 fiber. The unit structure is 19-inch chassis, and the height is generally 9cm. In a standard cabinet or rack. Users can choose the number of units or unit specifications according to actual needs. It can be used as fiber distribution, and can also be used as a cable terminal box; it can be separately assembled into a fiber distribution frame, or it can be integrated with a digital distribution unit and an audio distribution unit in a cabinet/frame to form integrated wiring. frame. The device is flexible in configuration, easy to install and use, easy to maintain, and easy to manage. It is one of the indispensable devices for small and medium-sized fiber-optic communication equipment rooms to realize fiber-optic, fiber-optic, frit, and fiber-optic cable access. Applicable to the fiber termination point in the fiber access network, with the wiring and welding function of the optical cable, which can realize flexible jumper and storage of the optical fiber core.

The above equipment for the fiber access network greatly improves the data transmission and processing capability of the fiber access network, and can bring two advantages:

First, the problem of remote transmission of the access line is solved, and the fiber access network is provided. The coverage is broader. In this way, the number of transit nodes of the entire overlay network can be reduced, and the structure of the network is made simpler.

Second, it can meet the needs of users for a variety of new broadband services and can improve the quality of new business data. This solves the “bottleneck” problem of the traditional copper access network from the core technology and lays the foundation for the realization of the “fiber to the home” dream.

Therefore, the future fiber access network should become the main force of the Internet information highway.

Original Article Source https://www.mscbsc.com/viewnews-39311.html