G.652 fiber is single-mode fiber.

In the late 1970s, attempts were made to replace the LED source with a successful long-life semiconductor laser to achieve longer communication distances and greater communication capacity, but mode noise occurs when the laser is transmitted in a multimode fiber. In order to overcome the mode noise, in 1980, a single-mode fiber with a zero-dispersion point at 1310 nm (non-dispersion-shifted single-mode fiber, referred to as standard single-mode fiber) was successfully developed. ITU-T recommends that this single-mode fiber be defined as G. 652 fiber.

Because the design idea of a single-mode fiber is to pass only one mode, the mode noise that occurs when transmitting in a multimode fiber does not occur. Therefore, in the mid-1980s, the 140Mbit/s fiber-optic communication system consisting of a laser source and a standard single-mode fiber had a relay distance and transmission capacity far exceeding that of the coaxial cable transmission system, thus gradually replacing the copper cable with the fiber-optic communication system. Communication has become the main means of communication adopted by the telecommunications industry.

The G.652 recommendation is the first version of V1.0 (10/1984) created by ITU-T Group 15 (1981-1984 study period). Later, after 1988, 1993, 1997, and 2000, the V5.0 version was formed. In V5.0, the basic types of G.652 fiber were subdivided into G.652A and G.652B… At the ITU-T15 meeting held in Geneva in 2003 [V6.0 (03/2003)], two types of G.652C and G.652D were added, and it was clarified that the L-band was limited to 1625 nm.

In 2005, some parameters were further revised to form the V7.0 (05/2005) version. The main changes are: MFD tolerance is reduced, the maximum dispersion slope, concentricity error, cladding out-of-roundness, microbend loss are reduced, and the coarse-wavelength division multiplexing optical interface G.695 is added.

In the mid-1980s, a dispersion-shifted fiber (DSF, Dispersion-Shifted Fiber) with a zero-dispersion wavelength shifted from 1.3 μm to 1.55 μm was developed in the mid-1980s for the characteristics that attenuation and zero dispersion were not at the same operating wavelength. The ITU has coded this fiber as G.653.

However, the dispersion-shifted fiber has a dispersion of 1.55 μm at zero, which is not conducive to multi-channel WDM transmission. When the number of channels used is large, the channel spacing is small, and four-wave mixing (FWM) occurs at this time to cause crosstalk between channels. If the dispersion of the fiber line is zero, the interference of the FWM will be very serious; if there is trace dispersion, the FWM interference will decrease. In response to this phenomenon, a new type of optical fiber, namely non-zero dispersion fiber (NZ-DSF), G.655, has been developed.

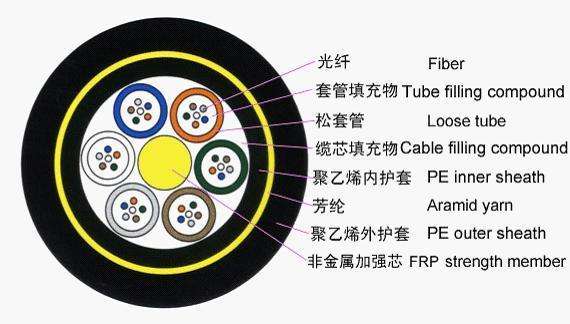

The fiber has a minimum dispersion near 1.3μm, which is called zero-dispersion wavelength. This is the reason why the early fiber optic communication uses 1.3μm as the working wavelength. If the fiber material and the radius of the fiber core are changed, the zero-dispersion wavelength will have corresponding Change. People can use multi-clad fiber to adjust the zero dispersion wavelength in the wavelength range of 1.25–1.65μm.

The fiber that shifts the zero-dispersion wavelength by 1.3μm is called dispersion-shifted fiber.

Disclaimer: All information indicated as other sources is transferred from other platforms, the purpose is to convey more information, does not represent the views and positions of this site. Please contact us if there is any infringement or objection.