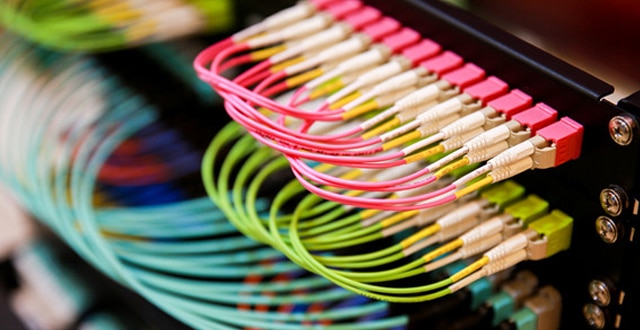

The optical fiber distribution frame is connected to the optical fiber connector. In the integrated wiring, the optical fiber distribution frame appears after the optical fiber appears, and the optical fiber generally appears in the vertical subsystem, then the problem comes, what is the optical distribution frame? classification? What are the functions of the fiber distribution frame? How to calculate the fiber distribution frame?

1. What are the classifications of optical distribution frames?

Unit type

A unitized fiber distribution frame is a unit in which multiple units are mounted, each unit is a separate fiber distribution frame. The patch panel not only retains the characteristics of the original small and medium-sized optical fiber distribution frame, but also provides space utilization through the structural deformation of the frame, and is a common structure in the early stage of the large-capacity optical fiber distribution frame. However, due to its inherent limitations in space provision, there is some inconvenience in operation and use.

Drawer type

The drawer type fiber distribution frame also divides a frame into a plurality of units, each unit consisting of one or two drawers. When welding and adjusting the thread, the corresponding drawer is pulled out to operate outside the rack, so that there is a large operation space, so that the units do not affect each other.

The drawer is provided with locking devices in both the pull-out and push-in states to ensure stable and accurate operation and safe and reliable connection of the components in the unit.

Although such a fiber distribution frame ingeniously provides a large space for the operation of the optical cable terminal, as with the unit type, the maximum convenience is not provided in the storage and deployment of the optical connection line. This type of rack is currently the most common form.

Modular

The modular structure divides the fiber distribution frame into a plurality of functional modules, the fusion, wiring, connection line storage and other functional operations of the optical cable are respectively completed in each module, and the modules can be assembled and installed in a common rack as needed. Inside. This structure provides maximum flexibility and better meets the needs of communication networks.

The modular high-capacity optical fiber distribution frame adopts a unique structure such as a panel and a drawer to make the welding and adjusting operation of the optical fiber more convenient. In addition, the vertical wire through and the intermediate distribution frame are used to effectively solve the cloth of the pigtail. Put and store problems. Therefore, it is the most popular type of large-capacity fiber distribution frame, but its cost is relatively high.

Second, what are the functions of the fiber distribution frame?

Optical fiber distribution frame plays an important role in the safe operation and flexible use of optical fiber communication networks, which are embodied in the following four aspects:

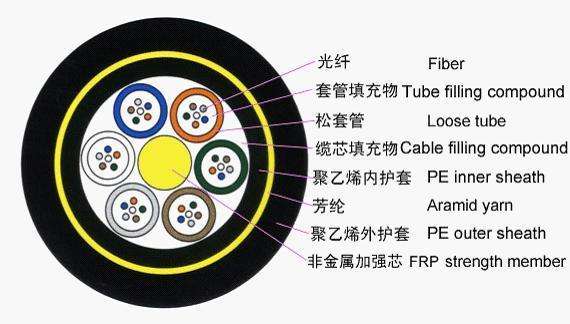

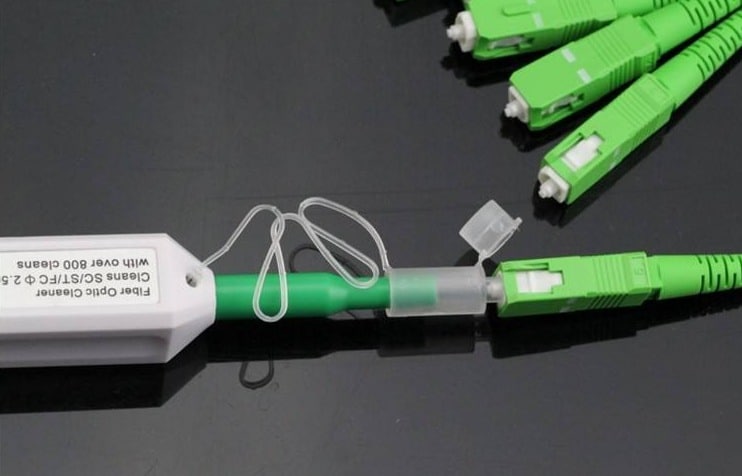

After the fiber jumper enters the rack, the fiber distribution frame can fix the fiber jumper to the frame, and mechanically fix the outer sheath and the reinforcing core to protect the fiber jumper from external mechanical damage.

The fiber distribution frame adopts a box structure, which saves space and optimizes cable management.

The high-density pre-terminated system used in fiber distribution frames enhances network performance and makes the network reliable and scalable.

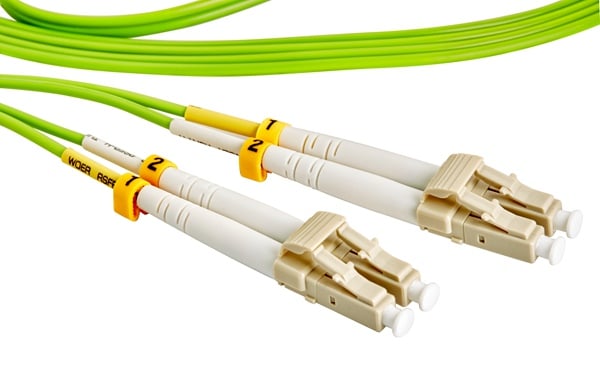

Fiber distribution frames enable easy and fast deployment of high-density interconnects and cross-connects in the data center, simplifying cabling deployments, increasing wiring density, and effectively reducing cabling failures and making cabling flexible.

Third, how to calculate the fiber distribution frame

Take 6-core indoor multimode fiber and 24-port fiber distribution frame as an example:

Assuming there are a central computer room and 5-floor wiring closets, then it is certain that there are 5 fibers.

At this time, the fiber distribution frame is 5 (one per floor wiring) +1 (one in the central room) = 6

Center room fiber distribution frame = 4 (4 core fiber) * 5 (5 fibers) = 20, 20 < 24, so only one is enough, if it is 10 fibers, it is 4 * 10 = 40, 40<48, at this time the center room needs 2 lights.

There is also a situation that is often encountered in actual operation. On the first floor, there is a central computer room and a floor wiring closet. In this case, if everything is in the same cabinet, the fiber can be combined into the same optical distribution. . for example.

6-core indoor multimode fiber and 24-port fiber distribution frame, one central computer room and 5-floor wiring closets

If the central computer room and the floor wiring closet on the 1st floor are on the 1st floor, there are 24 fiber points on the 1st floor (4*5+4), just one 24-port light is enough, so this time We can also solve the problem with 5 light distributions.

Regarding the knowledge about optical fiber distribution frames, today’s Xiaobian will explain to you here first. It is also an extremely important and complicated task in the selection of optical fiber distribution frames. We should fully consider various situations according to specific situations. Factors, based on repeated comparisons, can select a fiber distribution frame that best meets current needs and future development.

(This article is from the Internet, compiled and edited by thousands of hackers. If there is any infringement, please contact to delete.)

This article was first published in the thousand integrated wiring network: http://cabling.qianjia.com/html/2019-04/24_334470.html

Disclaimer: All information indicated as other sources is transferred from other platforms, the purpose is to convey more information, does not represent the position and position of the site and is responsible for its authenticity. If there is any infringement or objection, please contact us to delete.